Know the steps to get a beer like La Nena.

The brewing of a craft beer has nothing to do with the industrial process of the more commercial beers. That’s why its taste has nothing to do with them either. By opting for a craft process, not only are values and criteria chosen, but the consumer is also offered the guarantee of a truly delicious beer, with a pure and unrivalled taste.

The use of natural and artisanal techniques, heirs of the most traditional brewing tradition of our country, is present in each of the stages of production of La Nena beer, thus achieving a unique, fresh and natural product.

The production process is divided into four stages that we are going to go over little by little. Do you want to know a little bit more about each one of them?

Milling

In order to obtain the best beer, we need to take this process seriously, whereby the malt grain is milled. It is important that the grain is “crushed” in the right measure, as too much malt or too much flour would condition the whole process, inhibiting the quality we are looking for.

Maceration

Here we brew the barley infusion that will form the basis of our beer. To do this, we fill a boiler with water and heat it to the right temperature. We pour in our malt and leave it to macerate for the required time.

In this part of the process, certain very interesting moments take place. The artisans will vary the temperature of the pot in which we are cooking to ensure that the barley gives us its different properties at each moment: the extraction of the starch, the action of the enzymes, the obtaining of the sugar…

After the corresponding time, we remove the grain, thus obtaining the bagasse, which is nothing more than wet barley. At La Nena, all the materials are reused to make a sustainable and natural process. Therefore, our bagasse becomes food for livestock, a food highly appreciated by shepherds and farmers for its benefits for the animals.

Cooking

Right now, our draft beer is a thick, very sweet syrup. Now it is time to boil it with hops, the ingredient that will give it its definitive flavour. To do this, we will add hops in different stages to extract a different property from our precious plant in each one of them.

The first hop will give it the bitterness so characteristic of all beers.

The second hop gives it its flavour.

The third hop will add its characteristic aroma.

Of course, brewing times and the exact minute at which each hop is poured varies according to the recipe and type of beer, and each craft company has its own formula.

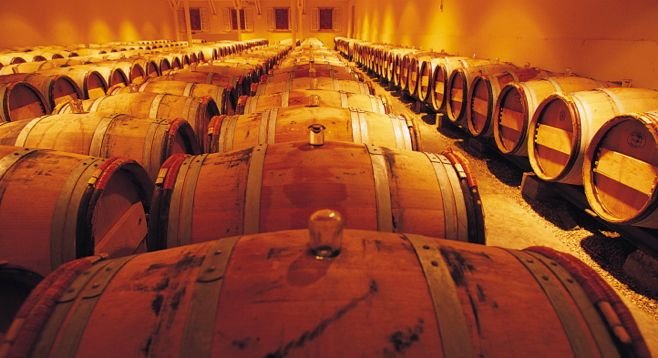

Fermentation

Once our broth has boiled and the hops have worked their magic, it is time to lower the temperature of the beer in order to proceed with fermentation.

The fermenter is the device that comes into play at this point. In it, we will pour our liquid and add the yeast, the last of the great ingredients that a beer needs and the one that performs the “miracle” of turning the wort into beer. The beer will go through two different fermentations:

The first fermentation lasts between five and ten days and, with it, we will achieve the final density of the product. Here it is very important to keep an eye on the temperature of the beer, which must be constant so that the process is not altered.

The second fermentation takes place after the beer has been bottled, at which point the beer finishes maturing and the final carbonation of our broth is generated naturally. Now it is a matter of waiting. The time to consider the beer ready varies depending on the style.

And now, it’s ready: let’s pour La Nena and enjoy the best of it!

Add Comment